The project

The furniture and construction sectors strongly rely on the extensive use of the Medium Density Fibreboard (MDF), an engineered and highly versatile wood-based material that displays valuable properties, such as smooth finish, machinability, strength and consistency. MDF is widely employed in the manufacture of kitchen cabinets and is well suited for residential construction of modern homes where cabinets and built-ins showcase the performance of MDF beautifully. It is the material of choice in home interiors where tight tolerances, smooth surfaces and intricate machining are critical.

Despite the remarkable performances that make the MDF an indispensable material for different sectors, these panels present serious drawbacks, namely the difficulty of recycling, their formaldehyde content (a toxic substance that works as binder) and the large depletion of natural sources caused by their production. In this context, the European furniture and construction industries are currently facing serious environmental challenges due to the extensive production and consumption of the unsafe and unsustainable MDF-made products.

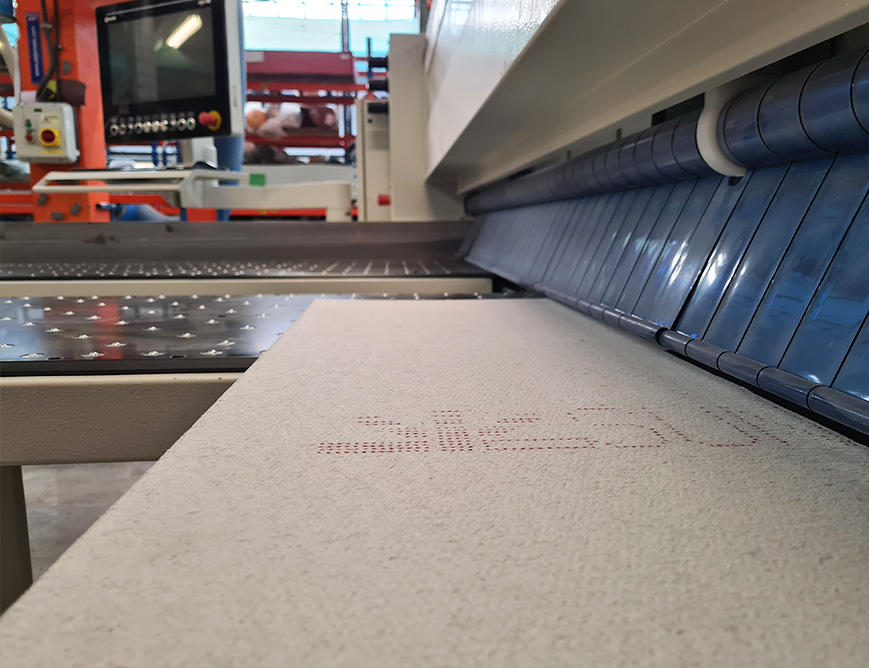

The LIFE B3 FURN will bring to the market the first formaldehyde-free wood panel made from 100% recycled material and 100% recyclable at end of life – called B3 Board (Board made with Bio-Based Binder) – with equal performance to the traditional MDF.

The innovative concept proposed in the project, i.e. making recyclable formaldehyde-free wood-based panels for furniture and construction, is based on the use of the premium Microfibrillated Cellulose (MFC)-mineral composite (FiberLean® MFC) produced by the project coordinator FiberLean Technologies Limited. When applied in fibreboards production process, the FiberLean® MFC shows unique properties ad binder, replacing toxic formaldehyde, improving product quality and reducing production cost.

Why is it good for the environment?

Waste generation: Furniture and construction sectors are main contributors to the enormous wood-based waste generated in Europe; the majority of which is destined for either landfill or incineration.

Use of formaldehyde: The wood fibres forming traditional MDF are combined with a binder of urea formaldehyde. Because of the presence of the UF, the MDF cannot be recycled at the end of its first-use life. Furthermore, formaldehyde is a well-recognised hazardous carcinogen and skin sensitizing agent. This poses severe hazard on furniture and construction workers who due to the prolonged exposure to formaldehyde have increased a risk of death caused by leukaemia as well as serious risks on consumers’ health, since formaldehyde may be released to indoor air as it is found in MDF articles present in a daily environment such as offices, homes, etc.

Resource depletion: The construction and furniture industries strongly rely on the extensive use of the MDF. The massive utilisation of virgin materials in place of recycled fibres is mainly caused by technical difficulties to obtain recycled MDF displaying mechanical properties comparable to the standard MDF. Therefore, through the extensive consumption of virgin materials, the furniture and construction industries contribute to the depletion of natural sources.

Why is it an innovation breakthrough?

The LIFE B3 FURN project strives to deliver a 100% recyclable board as a drop-in replacement of the non-recyclable wood-based panels.